White Fused Alumina for Wear-Resistant Insulating Ceramic Raw Material

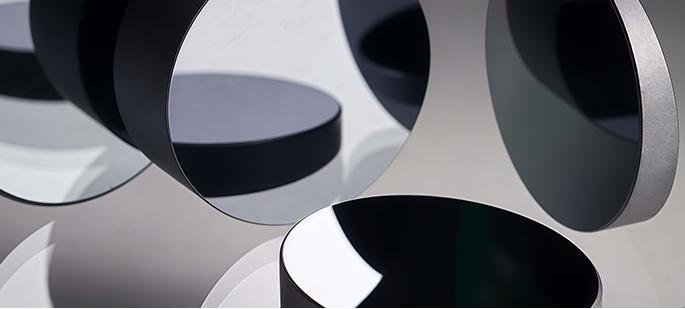

White fused alumina particles observed in ceramic sand under microscope

1. Application Overview

White fused alumina (WFA) is widely used as a high-purity, wear-resistant raw material in the production of insulating and structural ceramics. Its high hardness, thermal stability, and chemical purity make it ideal for components requiring excellent abrasion resistance and electrical insulation performance.

2. Application Scenarios

- • Electrical insulating ceramics: Ensures high dielectric strength and thermal resistance for insulators and substrates.

- • Wear-resistant components: Used in mechanical seals, valve seats, and cutting tools requiring high abrasion resistance.

- • Structural ceramics: Ideal for kiln furniture, wear plates, and other load-bearing ceramic parts.

- • Advanced ceramic composites: Combined with other ceramic powders to improve hardness, thermal stability, and corrosion resistance.

3. Recommended Particle Size

The particle size selection depends on the type of ceramic application and required sintering properties:

| Ceramic Type | Recommended Particle Size | Effect |

|---|---|---|

| Electrical insulators | 1 – 10 μm | High density, excellent insulation |

| Wear-resistant parts | 10 – 50 μm | Improved abrasion resistance |

| Structural ceramics | 20 – 100 μm | Uniform sintering, high mechanical strength |

| Ceramic composites | 5 – 50 μm | Optimized hardness and thermal stability |

Practical Tips

- Powder preparation: Ensure uniform particle size distribution and remove large agglomerates for consistent sintering.

- Sintering control: Maintain optimal temperature and atmosphere to achieve maximum density and strength.

- Mixing & additive selection: Combine with other ceramic powders or binders to achieve required mechanical and electrical properties.

- Quality monitoring: Test hardness, density, and dielectric properties to ensure high performance of finished ceramic components.