White Fused Alumina for Metal & Stainless Steel Polishing

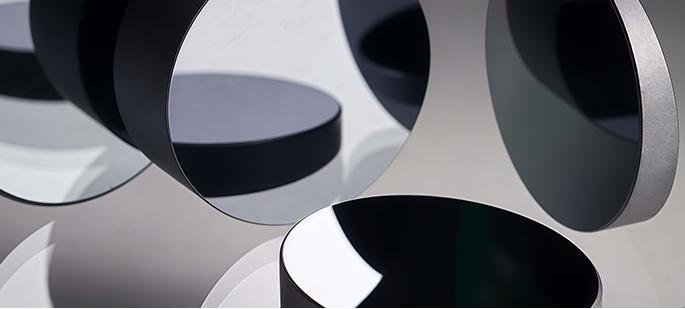

High-purity alumina powders for mirror polishing and precision finishing

1. Application Overview

White fused alumina (WFA) is a preferred abrasive for fine metal polishing due to its high hardness, chemical stability, and non-contaminating nature. It ensures smooth, reflective finishes on stainless steel, aluminum, and various precision components. Compared with traditional abrasives, WFA maintains a consistent polishing rate and delivers superior brightness without introducing iron impurities.

2. Application Scenarios

- • Mirror polishing of stainless steel: Produces a flawless reflective surface for decorative and industrial use.

- • Mold and die finishing: Ensures ultra-smooth cavity surfaces for precision forming and injection molding.

- • Polishing of aluminum and copper parts: Achieves uniform gloss without surface damage or contamination.

- • Kitchenware and hardware finishing: Used for final polishing of cutlery, handles, and stainless steel panels.

3. Recommended Grit Size

Choosing the right grit size is essential for achieving the desired polishing grade and surface smoothness. Below are suggested grit ranges for different polishing requirements:

| Application | Recommended Grit Size | Result |

|---|---|---|

| Rough surface leveling | F60 – F80 | Removes deep scratches, prepares for fine polishing |

| Intermediate polishing | F100 – F150 | Balances surface smoothness and efficiency |

| Fine mirror finishing | F180 – F320 | Produces high gloss and mirror-like reflection |

| Ultra-fine precision polishing | F400 – F800 | Extremely smooth finish for optical or electronic components |

Process Tips

- Particle size control: Use fine to micro-fine grades (F800–F2000) for mirror or satin finish polishing.

- Lubrication & slurry: Maintain adequate slurry flow or oil-based lubricant to minimize surface scratches.

- Polishing speed & pressure: Adjust based on metal type—apply moderate speed and light pressure for stainless steel.

- Surface evaluation: Inspect gloss level, reflectivity, and micro-scratch density to ensure consistent finish quality.