White Fused Alumina for Silicon Wafer Cutting

Precise wafer slicing using white fused alumina slurry in multi-wire saws

1. Application Overview

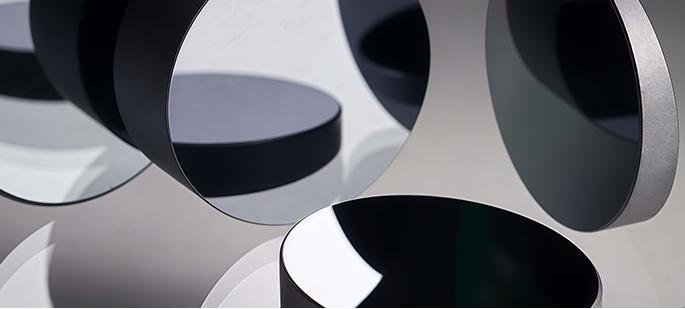

White fused alumina (WFA) is widely used as an abrasive in slurries for multi-wire saw slicing and in certain dicing and grinding processes for silicon wafers. Due to its high hardness, chemical stability and narrow particle-size distribution, WFA provides consistent cutting performance, good thermal stability, and minimal contamination — all critical for semiconductor and photovoltaic wafer processing.

In wire-sawing, abrasive particles are suspended in a water-based slurry and carried into the gap between silicon ingot and moving wires; the cutting action is a combination of micro-cutting and micro-fracture by abrasive impacts. Choosing an appropriate particle size and concentration helps balance slicing speed, kerf loss, and surface/subsurface damage.

2. Application Scenarios

- • Multi-wire saw slicing for silicon wafers: Used in slicing mono- and multi-crystalline silicon ingots into thin wafers (semiconductor and solar industries).

- • Slurry-based cutting for PV wafers: Preferred in photovoltaic wafer production where high throughput and acceptable kerf loss are required.

- • Pre-grinding before lapping/polishing: Coarser WFA grades can be used to remove saw-induced damage prior to fine grinding and CMP (chemical mechanical polishing).

- • Dicing and singulation support: In some dicing-slurry setups and abrasive-assisted dicing, controlled WFA grades help achieve cleaner cuts.

3. Recommended Particle Sizes

Particle size selection depends on the slicing equipment, desired wafer thickness, kerf-loss tolerance, and subsequent processing (edge quality and subsurface damage removal). Below are typical particle-size ranges commonly used in wire-saw and slurry cutting processes:

| Process Stage | Typical Particle Size | Effect |

|---|---|---|

| Coarse slicing (fast throughput) | ~20 – 50 μm (approx. F60–F150) | Higher cutting speed, larger kerf loss and deeper subsurface damage; typically used for rough slicing. |

| Standard wafer slicing | ~5 – 20 μm (approx. F150–F400) | Good balance of slicing speed and surface/subsurface quality; widely used in PV wafer production. |

| Fine slicing / low-damage cutting | <5 μm (submicron to ~3–5 μm, F400+) | Lower kerf loss and reduced subsurface damage, slower cutting; used where minimal damage is critical. |

| Post-saw pre-grinding | Variable, commonly 10–50 μm | Used to remove saw marks and prepare surface for lapping/polishing. |

Note: the conversion between micron sizes and nominal F-grit labels is approximate — manufacturers may use different classification systems. For best results, test particle sizes and slurry concentrations under your specific saw conditions (wire speed, tension, cooling) and downstream process requirements.

Process Tips

- Slurry concentration: Typical slurry solids concentration ranges from 1% to 10% by weight; optimize to avoid excessive wire wear or clogging.

- Filtration & recycling: Use proper filtration to remove large contaminants and maintain a stable particle-size distribution for consistent cutting.

- Cooling and lubrication: Maintain sufficient flow and temperature control to reduce thermal damage and improve cutting life.

- Quality control: Monitor kerf loss, surface roughness, and subsurface damage; adjust grit size and slurry parameters accordingly.