White Fused Alumina for Sandblasting & Rust Removal

Efficient surface cleaning using white fused alumina abrasive

1. Application Overview

White fused alumina (WFA) is one of the most efficient and clean abrasive materials for industrial sandblasting. With a Mohs hardness of 9.0, sharp angular grains, and high purity, it can effectively remove rust, oxide layers, and old coatings from metal surfaces without causing iron contamination.

2. Application Scenarios

- • Stainless steel and aluminum surface cleaning: Removes rust, weld marks, and oxide layers without affecting surface brightness.

- • Steel structure & pipeline rust removal: Provides uniform roughness for coating and painting preparation.

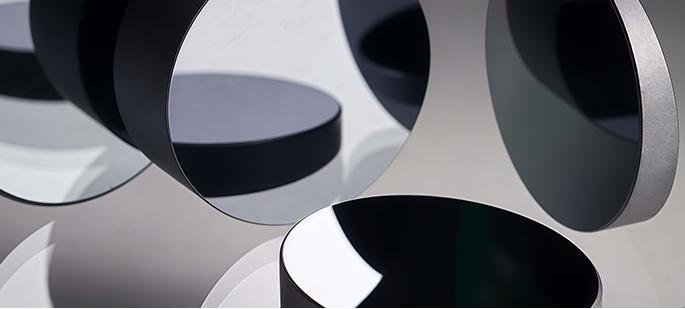

- • Glass and ceramic etching: Creates a fine frosted texture, ideal for decorative and functional surfaces.

- • Automotive and aerospace components: Used for cleaning precision metal parts to ensure bonding or coating adhesion.

3. Recommended Grit Size

Choosing the right grit size depends on the desired surface roughness and the hardness of the substrate. Below are typical recommendations for different sandblasting applications:

| Application | Recommended Grit Size | Effect |

|---|---|---|

| Steel structure rust removal | F12 – F36 | Fast cleaning speed, coarse roughness |

| Stainless steel pre-treatment | F46 – F80 | Clean surface, good adhesion for coating |

| Aluminum & copper parts | F80 – F120 | Smooth and bright finish |

| Glass etching | F150 – F240 | Delicate frosted surface |

Process Tips

- Abrasive size selection: Choose medium to coarse grit (F24–F60) for efficient rust and paint removal.

- Air pressure control: Maintain stable blasting pressure (0.5–0.7 MPa) to achieve uniform surface cleaning without substrate damage.

- Nozzle distance & angle: Keep 100–200 mm distance and a 45°–70° angle for optimal cleaning and reduced media loss.

- Post-cleaning inspection: Check for residual rust, oil, or uneven texture before coating or painting.