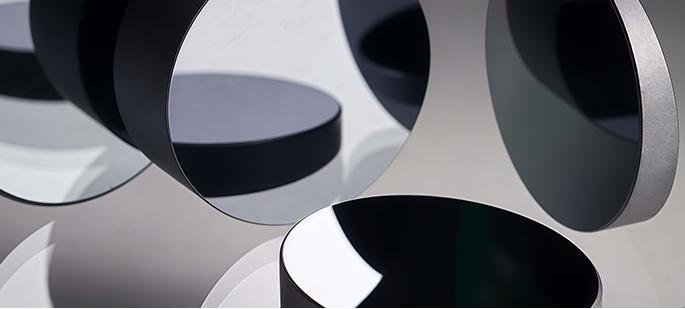

White Fused Alumina for Optical & LED Polishing

High-precision polishing for lenses, LEDs, and display panels

1. Application Overview

White fused alumina (WFA) is widely used for high-precision polishing of optical lenses, LED chips, and display panels. Its uniform particle size, high purity, and sharp angular grains provide excellent material removal rate while minimizing surface defects.

2. Application Scenarios

- • Lens and optical component polishing: Produces smooth, defect-free surfaces for cameras, microscopes, and telescopes.

- • LED wafer and chip polishing: Ensures flatness and surface quality for improved light efficiency.

- • Display panel finishing: Removes micro scratches and creates uniform, high-gloss surfaces for LCD, OLED, and touchscreens.

- • Semiconductor CMP applications: Compatible with chemical-mechanical polishing processes for wafer back-grinding and CMP planarization.

3. Recommended Grit Size

The selection of white fused alumina grit size depends on the level of surface finish required and the hardness of the substrate. Typical recommendations are:

| Application | Recommended Grit Size | Effect |

|---|---|---|

| Coarse lens grinding | F180 – F320 | High material removal, prepares for fine polishing |

| Fine lens polishing | F400 – F800 | Smooth, scratch-free optical surface |

| LED wafer planarization | F600 – F1200 | Flat surface, high light extraction efficiency |

| Display panel finishing | F800 – F1500 | Uniform high-gloss finish, micro-scratch removal |

Process Tips

- Slurry preparation: Maintain consistent concentration and particle distribution for uniform polishing.

- Temperature control: Avoid overheating to prevent surface defects and reduce thermal stress.

- Polishing pads and pressure: Adjust pad hardness and applied pressure according to substrate hardness.

- Inspection & quality control: Monitor surface roughness, gloss, and micro-scratches to ensure product quality.